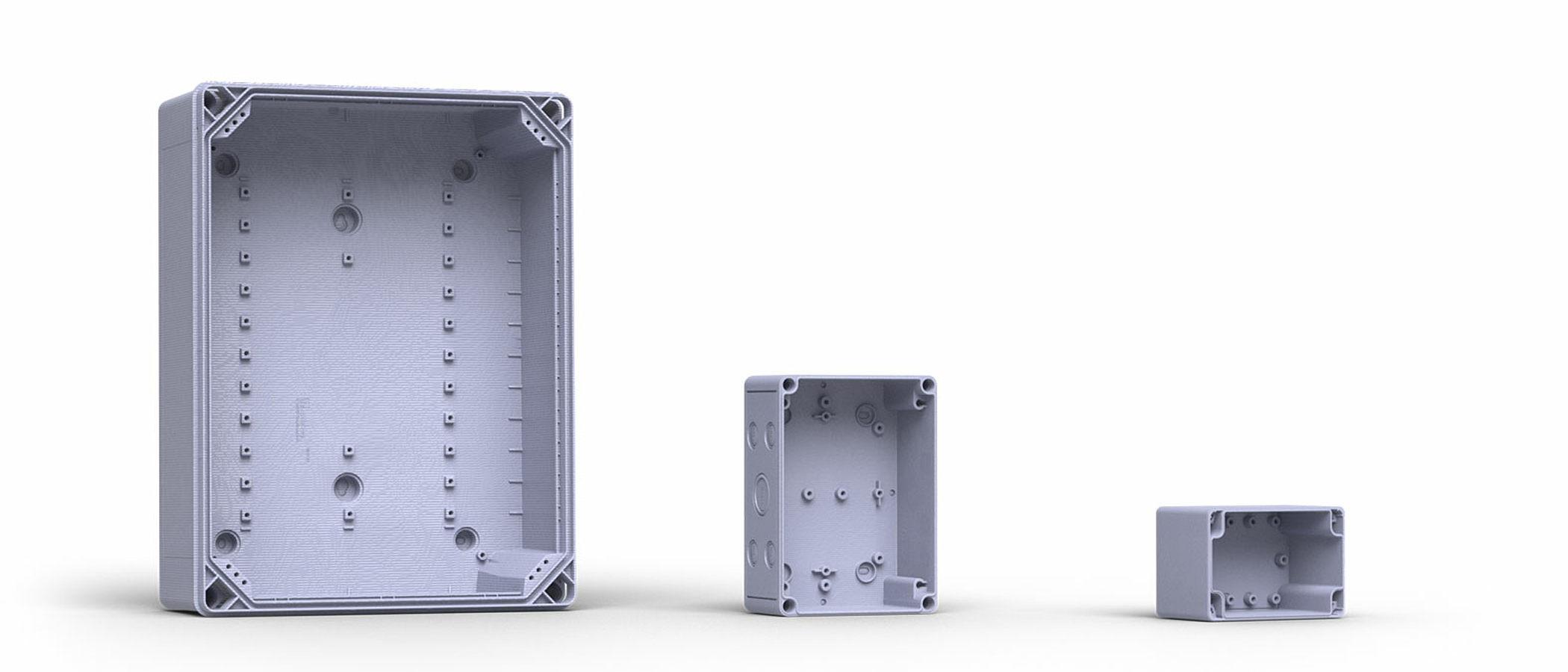

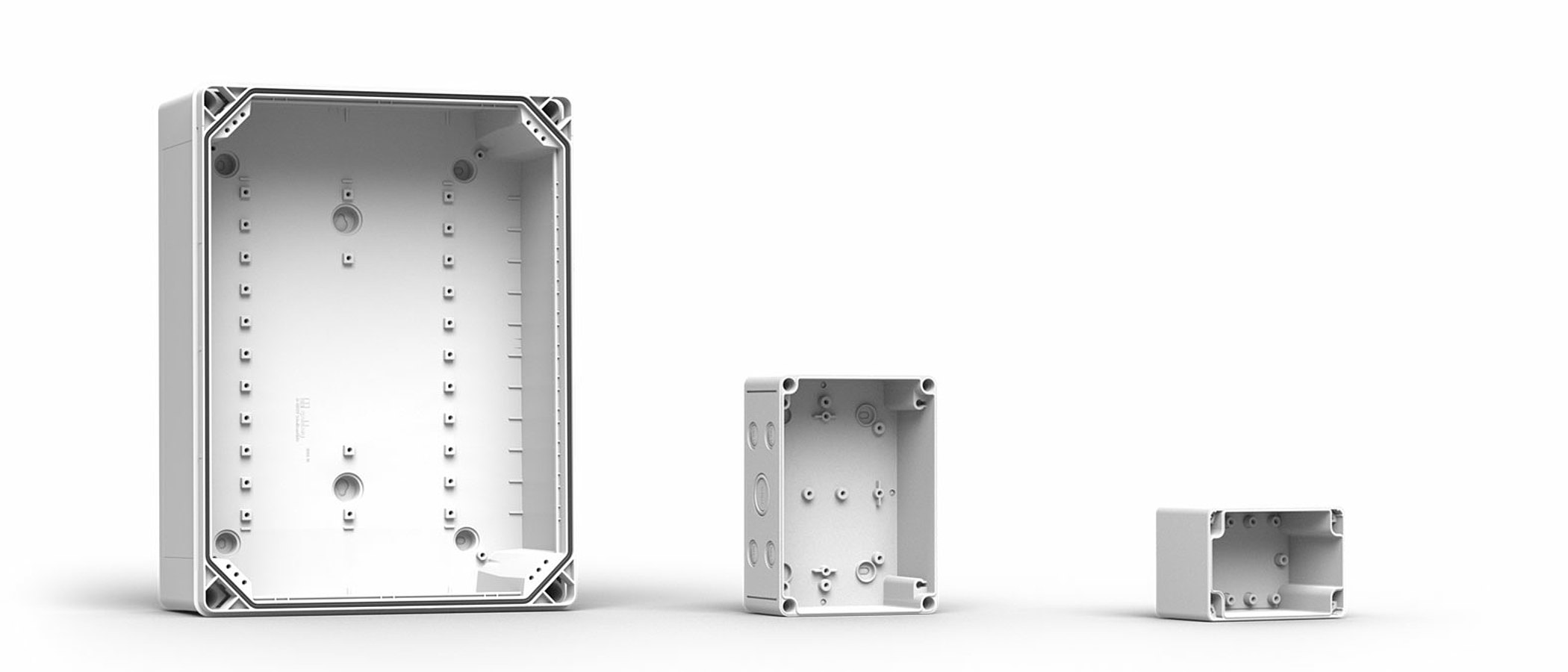

At Spelsberg, we attach great importance to every part of our process chain, no matter how small, and use modern processes, the latest plant technology and highly qualified employees to ensure that everything is just right in the end. In order to leave nothing to chance, we pool all the expertise we need for the development and manufacture of our premium enclosures in-house. Whether development and design, toolmaking, certification or further processing steps such as the assembly of electrical and mechanical installation components and customized printing: only those who do everything themselves have all the parameters under control and can deliver absolutely high-quality, made-to-measure enclosures.

In recent years, we have greatly expanded the customizing area in order to be able to respond even faster and better to individual customer requirements. We believe that producing standard goods in large quantities is not an art.