Melting temperature

The melting temperature of thermoplastics must be adjusted precisely. The correct cutting data and millers must be used here.

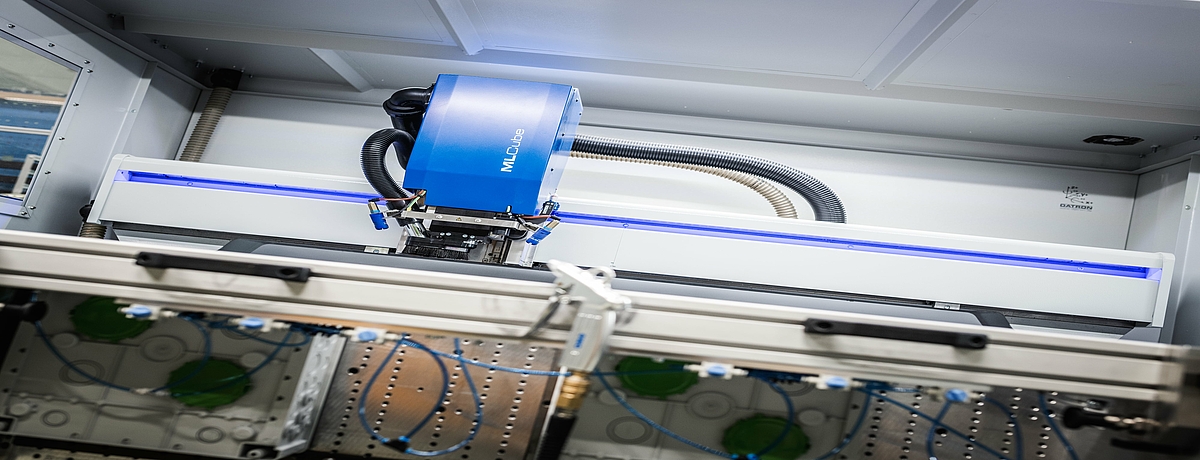

Cooling

Cooling with compressed air or drilling emulsion reduces temperature-related problems.

Clamping

In order to keep plastic plates free of strain, they are affixed using vacuum technology before processing. This is important to prevent twisting and to obtain good edges.

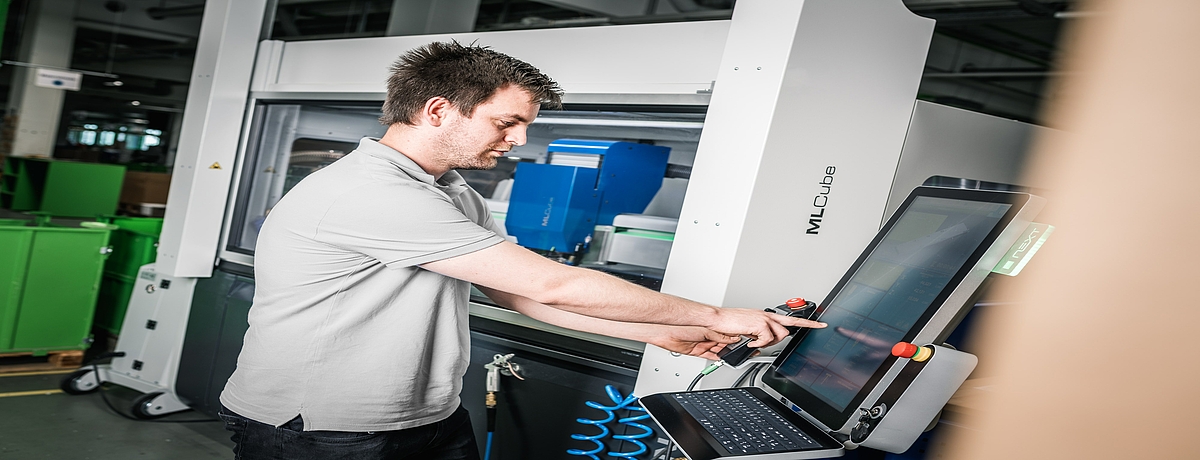

Tool selection

Our production department works with the most modern, well maintained and, above all, sharp tools to guarantee exact results.

Deburring

When milling plastic, unattractive burrs often occur. They are removed professionally by our employees before you receive the enclosure.

Health

Wherever plastic is being processed with chipping procedures, very fine fibres occur, which have no place in breathable air. In order to protect our employees, we have taken various safety measures. Therefore, a powerful extraction system removes all particles right where they occur. Wearing mouth protection is also obligatory for all processors.