Along with turning and milling, drilling belongs to the machining procedures with a geometrically-defined blade. When drilling, the tool normally rotates around its own axis and carries out the cutting movement. This generates heat at the trip of the drill, which is difficult to counteract due to its location. Depending on the material, there are drills with very different properties, which are for example able to remove chips or feed coolant.

For soft and ductile materials that may chip easily, the feed and the circular movement during the main cutting process cause the actual chip removal procedure. This is not possible in the centre of the drill, as the cutting speed only reaches its maximum on the outside and is 0 m/s on the inside due to rotating around its own axis, which means that plastic deformation at best can be achieved here. For this reason, spiral drills have a cross-cutter on their tips and special drills for soft materials have a pronounced tip.

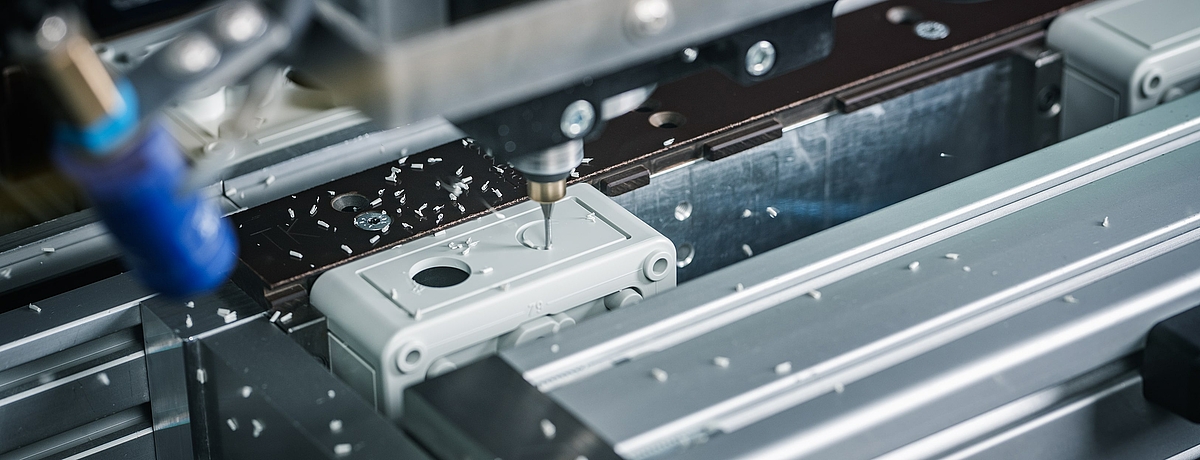

The experts from Spelsberg know exactly which tool is right for the respective material and therefore ensure precise results within the required tolerances.